Introduction

Understanding SF6 and Its Prevalence in Switchgear

Sulphur hexafluoride (SF6) is a man-made gas with exceptional electrical insulation properties. It is widely used in the power industry, especially in high-voltage switchgear such as circuit breakers, gas-insulated switchgear (GIS), and disconnectors. SF6 allows for more compact equipment designs due to its high dielectric strength, which is roughly three times greater than that of air. Its ability to effectively quench electrical arcs also reduces the risk of fire and equipment damage. These properties have led to its adoption in densely populated areas and critical infrastructure where reliability and space are paramount.

Why the Transition Matters Now

While SF6’s technical merits are well-established, the environmental consequences are increasingly difficult to ignore. SF6 is the most potent greenhouse gas listed under the Kyoto Protocol, with a global warming potential (GWP) 23,500 times greater than CO2. Even small leaks can significantly contribute to climate change. Regulatory bodies, environmental groups, and forward-thinking businesses are calling for a shift away from SF6 use. As part of global efforts to mitigate climate change, transitioning to SF6-free technologies is not only a responsible choice but an increasingly necessary one.

Purpose of This Article

This article aims to provide a comprehensive overview of the environmental arguments for replacing SF6 in switchgear. It will delve into the drawbacks of SF6, explore available alternatives, outline the benefits of the transition, and address the challenges. Special focus will be given to how Cambridge Sensotec can support this shift through its technological expertise and solutions.

What is SF6 and Why Has It Been Used?

SF6 is a chemically stable, non-flammable gas that has been used since the 1950s in the electrical power industry. Its insulating and arc-quenching abilities make it indispensable in high-voltage environments. One of the key reasons for its widespread use is that it enables more compact and efficient switchgear designs, particularly important in urban or space-limited settings. Equipment using SF6 is also known for its long service life and reliability, often lasting several decades with minimal maintenance. These benefits have entrenched SF6 as a standard in electrical infrastructure worldwide.

The Environmental Impact of SF6

SF6 is classified as a fluorinated gas (F-gas), and its environmental footprint is substantial. It is 23,500 times more harmful to the atmosphere than carbon dioxide when it comes to trapping heat, and it can remain in the atmosphere for up to 3,200 years. Even though the quantities used may seem small, the impact is disproportionately large. Leaks can occur during installation, maintenance, and disposal, as well as through slow seepage over time.

The European Union has responded by including SF6 in its F-Gas Regulation, mandating strict measures for containment, reporting, and reduction. Countries like Germany and the Netherlands have taken proactive steps, introducing policies to phase out SF6 in new equipment. Globally, the Kigali Amendment to the Montreal Protocol is also putting pressure on industries to adopt low-GWP alternatives.

Alternatives to SF6 & Transitioning to S6-free Switchgear

Technological advancements have produced several viable alternatives to SF6:

- Vacuum Interruption: In medium-voltage applications, vacuum circuit breakers (VCBs) are already widely used. They extinguish arcs in a vacuum chamber and require no gas, eliminating the environmental risks associated with SF6.

- CO₂ and Air-Insulated Solutions: Clean air and CO₂ can be used as insulating media in both medium- and high-voltage equipment. These gases have negligible environmental impacts and are readily available, though they often require slightly larger equipment designs.

- Fluoronitrile and Fluoroketone Mixtures: These synthetic alternatives offer similar insulation properties to SF6 but with dramatically lower GWPs. For example, fluoronitrile-based gases can reduce the GWP by more than 99% compared to SF6.

Though the initial investment for SF6-free technologies can be higher, the total cost of ownership tends to be lower. Reduced maintenance, regulatory compliance savings, and environmental benefits offset the upfront costs. Case studies from utilities in Europe and Asia show that these alternatives are practical and reliable even under demanding conditions.

Benefits of Transitioning to SF6-free Switchgear

Transitioning to SF6-free switchgear yields a range of benefits:

- Environmental Sustainability: By eliminating a high-GWP gas, organisations significantly reduce their carbon footprint and contribute to global climate goals.

- Corporate Social Responsibility (CSR): Companies demonstrate environmental responsibility and enhance their reputations by proactively reducing harmful emissions.

- Reduced Risk and Liability: The dangers of SF6 leaks—both regulatory and operational—are avoided. Alternative technologies are often safer and simpler to handle.

- Long-Term Financial Gains: While capital costs may be higher, long-term savings arise from reduced regulatory burden, simpler maintenance, and improved energy efficiency. These savings can make the investment highly cost-effective over the product lifecycle.

Challenges and Considerations

Despite the benefits, several challenges must be addressed:

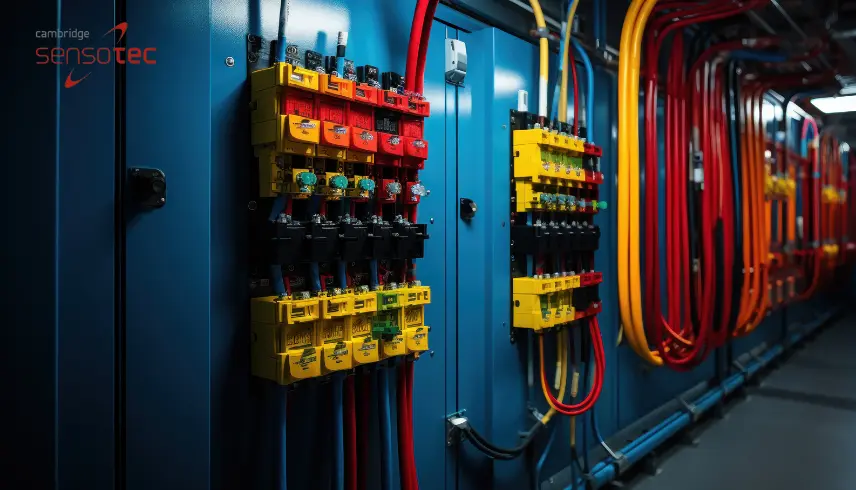

- Retrofitting Infrastructure: Most current switchgear is built around SF6 technology. Transitioning involves either full replacement or careful retrofitting, both of which can be costly and time-consuming.

- Upfront Costs: SF6-free solutions often require greater initial investment. Access to green financing and government incentives can help mitigate this.

- Workforce Training: Maintenance teams need training to understand the properties and handling of new gases or vacuum systems. This includes health and safety protocols, operational procedures, and emergency responses.

- Supply Chain Limitations: Availability of SF6-free products can vary depending on the region and supplier. Strategic sourcing and early procurement planning are essential to avoid delays.

Strategic Approach to Transitioning to SF6-free Switchgear

A successful transition to SF6-free switchgear starts with a comprehensive audit of existing systems. Understanding where and how SF6 is used provides the foundation for a phased transition strategy. Partnering with experienced providers like Cambridge Sensotec is critical—they offer not only reliable technologies but also guidance on regulatory compliance and environmental reporting.

Developing a roadmap ensures that the transition is cost-effective and operationally smooth. This plan should include setting internal policies, updating procurement criteria to prioritise low-GWP technologies, and embedding sustainability into long-term planning.

Cambridge Sensotec’s Role

Cambridge Sensotec supports the transition in several key ways:

- Advanced Gas Analysis: Our Rapidox analysers enable precise monitoring of SF6 alternatives, ensuring proper gas composition and equipment performance.

- Compliance Support: The company’s tools assist in adhering to F-Gas regulations and broader environmental standards, reducing legal and reputational risk.

- Expert Consultation: Cambridge Sensotec offers technical guidance tailored to each client’s infrastructure and operational needs, helping to create customised, future-proofed solutions.

Looking Ahead To Transitioning to SF6-free Switchgear

The global energy sector is moving rapidly towards decarbonisation. Digitalisation, automation, and electrification are transforming the way energy is produced, distributed, and consumed. SF6-free switchgear is at the forefront of this change, offering a cleaner, safer, and more sustainable option.

Continued innovation in materials science and engineering is making SF6 alternatives more cost-effective and efficient. Government policy and industry collaboration will play a pivotal role in driving adoption at scale, especially in emerging markets.

Recap

SF6 has served the energy sector well, but its environmental impact can no longer be overlooked. With reliable alternatives now available, and with mounting regulatory and societal pressure, the time for change is now. Companies that lead the way in transitioning to SF6-free technologies will not only future-proof their operations but also play a vital role in the global fight against climate change. For businesses like Cambridge Sensotec and their clients, this represents both a responsibility and an opportunity to make a lasting, positive impact.