Introduction to Collaborations on SF6

Why SF6 Industry Collaborations Matter

Sulphur hexafluoride (SF6) is a critical gas used across a range of high-voltage electrical applications. It has unique properties such as nonflammability, high dielectric strength, and strong arc quenching ability, making it essential to the energy sector. However, SF6 also happens to be one of the most potent greenhouse gases, with a global warming potential over 23,000 times greater than carbon dioxide. In an era of mounting environmental responsibility, this has led to intensified scrutiny and an urgent call for innovation. Collaborations within the SF6 industry has emerged as a powerful mechanism to address both the environmental challenges and the need for modernisation in the energy and manufacturing sectors. By joining forces, businesses, regulatory bodies, and research institutions can collectively pave the way toward sustainable solutions without compromising safety or performance.

Purpose and Scope of This Article

This article delves into the ecosystem of SF6 industry collaborations, spotlighting the impact of partnerships between manufacturers, utility providers, academic researchers, and technology innovators. We will also explore Cambridge Sensotec’s leading role in this collaborative movement and how joint efforts are shaping the future of SF6 usage and alternatives. Whether you’re a professional in the energy sector, a policymaker, or simply interested in green technology, this guide provides valuable insights into how collaboration is driving change in the world of SF6.

Understanding SF6 and Its Industrial Importance

What is SF6?

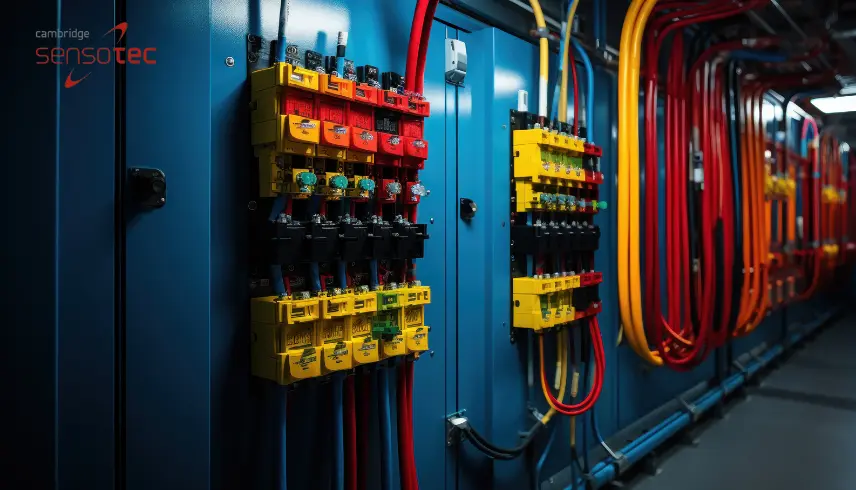

SF6, or sulphur hexafluoride, is an inorganic, colourless, odourless, non-flammable, and extremely potent greenhouse gas. It is widely used in the electrical industry due to its excellent insulation and arc-interrupting capabilities. The gas is commonly found in gas-insulated switchgear (GIS), circuit breakers, and other electrical equipment designed to prevent electrical faults and ensure operational safety.

Key Applications Across Industries

Although predominantly utilised in the energy and utility sectors, SF6 finds use in several other industries:

- Electrical Transmission and Distribution: Essential for insulating high-voltage switchgear.

- Semiconductor Manufacturing: Used as a plasma etching gas due to its chemical stability.

- Medical Applications: In small quantities, SF6 is used in certain types of imaging and surgical procedures.

- Magnesium and Aluminium Industries: Acts as a shielding gas during casting processes.

These applications highlight the gas’s versatility, though they also underscore the challenge of balancing performance with environmental impact.

Environmental and Regulatory Considerations

Although SF6 is highly effective, it faces growing scrutiny due to its significant global warming potential. It is non-toxic and chemically stable, but its estimated atmospheric lifetime of 3,200 years means that even small emissions can cause long-term environmental harm.

Governments and international organisations are responding with stricter regulations. The European Union’s F-Gas Regulation and the US Environmental Protection Agency’s initiatives are just a few examples aiming to monitor and reduce SF6 emissions. These evolving regulations create an urgent need for industries to innovate and collaborate, developing safer alternatives and improving containment practices.

The Role of Collaboration in the SF6 Sector

Industry Challenges That Require Partnership

The continued use of SF6 poses several challenges that are too complex for any single organization to address alone. These challenges include:

Environmental Pressures

With SF6 extremely high global warming potential, the pressure to reduce or eliminate its emissions is immense. Collaborative efforts are essential to explore alternatives, share emission-reducing technologies, and adopt best practices industry-wide.

Technological Advancements

Developing next-generation electrical equipment that functions without SF6, or with a reduced environmental footprint, demands joint R&D between manufacturers, research bodies, and end-users. Collaborations accelerate product development and shorten the time to market for sustainable solutions.

Regulatory Compliance

Evolving international legislation requires a cohesive and informed response. Collaborative networks help companies interpret and comply with regulatory shifts while influencing policy through joint advocacy.

Why Partnerships Are Critical to Innovation

The complexity of replacing or minimising SF6 means that innovation cannot happen in silos. Partnerships open the door to shared expertise, pooled resources, and collective risk management. Industry collaborations enable:

- Shared testing and validation of new materials.

- Pilot programmes across various geographical and operational conditions.

- Standardisation of equipment and monitoring tools.

Collaboration not only drives compliance and innovation, but it builds resilience and ensures industry relevance in a changing world.

Cambridge Sensotec’s Role in the Collaborative Ecosystem

Strategic Alliances and Technical Partnerships

Cambridge Sensotec analysers are designed to support emerging technologies, with a key focus on reducing SF6 emissions and enabling the transition to SF6-free alternatives.

Through years of technical development, the company contributes to improving gas-handling procedures and refining leak detection methods, ensuring that partners maintain the highest standards of safety and efficiency.

Contributions to SF6 Analysis and Monitoring Innovation

As a manufacturer of high-precision gas analysis instruments, Cambridge Sensotec plays a vital role in enhancing the reliability and traceability of SF6 monitoring. Their flagship product line, Rapidox, is designed to provide real-time, multi-gas analysis, supporting utilities and manufacturers in reducing emissions and staying compliant with evolving legislation.

Working in tandem with its collaborators, the company also helps develop portable and fixed systems tailored to diverse operational environments—from substations to research labs—ensuring seamless integration with emerging smart technologies.

Commitment to Sustainable Practices

Sustainability is at the core of Cambridge Sensotec’s operational philosophy. The company is actively involved in projects focused on SF6 recycling and gas lifecycle management. By collaborating with partners across the value chain, they contribute to a circular economy model, which includes gas reclamation, reconditioning, and safe reuse.

Their efforts underscore a broader commitment to environmental stewardship, showcasing how a forward-thinking SME can influence industry standards and support the global push for greener technology.

Innovation Through Shared Knowledge and Technology

Co-Development of Next-Gen Detection Tools

The shift toward SF6 alternatives and tighter emission controls has intensified demand for sophisticated detection and monitoring tools. Co-development efforts between analytical experts and manufacturers have led to innovations in infrared sensing, acoustic detection, and AI-based diagnostics.

By pooling knowledge and resources, partners accelerate the development cycle and ensure that the resulting technologies are robust, field-tested, and aligned with regulatory benchmarks.

Joint R&D in SF6 Alternatives and Gas Recovery

Research and development efforts shared between universities, gas suppliers, and industrial stakeholders have resulted in promising SF6 substitutes, new infrastructures and new gas mixtures. These collaborations not only support chemical innovation but also optimise the equipment needed to handle, store, and deploy these alternatives safely.

In parallel, joint initiatives in gas recovery and recycling are helping extend the life cycle of existing SF6 stocks while reducing the environmental burden. Cambridge Sensotec, for instance, plays a role in validating the purity and usability of reclaimed gas using its precision instruments.

Cross-Sector Knowledge Transfer

One of the most powerful aspects of SF6 industry collaboration is the transfer of knowledge across sectors. Lessons learned in semiconductor manufacturing, for instance, are being applied to the energy sector, particularly around high-precision gas handling and cleanroom standards.

Such cross-pollination ensures that the entire value chain benefits from innovation, even when it originates outside traditional boundaries. Through conferences, joint publications, and digital platforms, partners create a shared knowledge base that serves as a catalyst for systemic change.

Global Impact of SF6 Collaborations

Meeting International Emissions Goals

Collaborative efforts in the SF6 sector are instrumental in aligning with global climate targets such as the Paris Agreement and the EU Green Deal. By working together, organisations can harmonise reporting practices, share mitigation strategies, and leverage economies of scale to reduce emissions more effectively.

Such alignment strengthens credibility and enables companies to demonstrate compliance and commitment to sustainability on the international stage.

Supporting a Greener Electrical Infrastructure

As countries strive to decarbonise their power grids, SF6 collaborations have a direct impact on making electrical infrastructure greener. This includes deploying SF6-free technologies in substations, adopting modular switchgear designs, and integrating renewable energy sources without compromising grid reliability.

Collaborations between governments, utilities, and manufacturers foster pilot projects that prove feasibility and drive wider adoption of eco-efficient technologies.

Advancing Industry 4.0 and Smart Grids

The convergence of SF6 innovations with digitalisation trends is accelerating the transition to smart grid infrastructure. Through partnerships, stakeholders are embedding sensors, IoT devices, and AI-driven analytics into SF6 monitoring systems.

These developments not only reduce the carbon footprint of operations but also enable real-time decision-making, predictive maintenance, and more resilient grid management. Collaborative innovation is thus a cornerstone of both environmental sustainability and technological progress.

Future Outlook for SF6 Industry Collaborations

Emerging Players and New Markets

The landscape of SF6 collaboration is expanding as new players enter the market. Start-ups focusing on environmental technologies, sensor innovation, and gas alternatives are increasingly sought as partners by legacy manufacturers and energy companies. These dynamic entrants bring agility and fresh perspectives that challenge traditional approaches.

Furthermore, emerging economies with rapidly expanding energy needs offer new markets where collaborative frameworks can be established from the beginning, helping to avoid the pitfalls of legacy systems.

The Role of Digitalisation and AI

As digitalisation continues to revolutionise industrial processes, its integration into SF6 systems is inevitable. AI-driven analytics, machine learning, and IoT technologies are being used to predict maintenance needs, detect anomalies, and optimise system performance.

Future collaborations will increasingly centre around these technologies, where data sharing and interoperability become key to success. Collaborative digital ecosystems will play a pivotal role in ensuring both environmental and operational efficiency.

Trends in Sustainability and Green Innovation

Sustainability will remain a guiding principle in all future SF6 partnerships. Trends indicate growing investment in carbon offset strategies, circular economy models, and transparent sustainability reporting. Collaborative efforts that embed these principles will be more attractive to stakeholders, regulators, and end-users alike.

Partnerships that promote education, workforce development, and ethical sourcing will further strengthen the industry’s alignment with global sustainability goals.

Recap

The Power of Collaborations in the SF6 Landscape

In an industry defined by complexity and high stakes, collaboration is more than a strategy, it’s a necessity. Whether it’s developing SF6 alternatives, refining monitoring technologies, or setting global standards, partnerships lie at the heart of progress.

Cambridge Sensotec and other forward-thinking organisations demonstrate how collaborative ecosystems can deliver innovative, scalable, and sustainable solutions that meet both current and future demands.

Embracing Collaborative Transformation

The future of the SF6 industry depends on its ability to embrace collaborative transformation. As environmental regulations tighten and technological opportunities expand, those who engage in meaningful partnerships will be in the best position to lead.

Now is the time for manufacturers, utilities, researchers, and policymakers to come together. Through shared vision, resources, and responsibility, the SF6 industry can turn challenges into catalysts for enduring, positive change.