Introduction

As the energy sector continues to transition towards more sustainable practices, the spotlight is increasingly falling on infrastructure. One of the most pressing issues is the use of sulphur hexafluoride (SF6) in switchgear. While SF6 has been the go-to insulating gas in high-voltage switchgear for decades, its environmental impact is now difficult to ignore. With a global warming potential (GWP) more than 23,000 times that of CO2, SF6 is one of the most potent greenhouse gases in existence. As regulatory pressures mount and public demand for climate-conscious solutions grows, the industry is turning its attention to SF6-free switchgear. These next-generation technologies are safer, more sustainable, and fully aligned with the future of energy distribution.

The Problem with SF6 in Modern Infrastructure

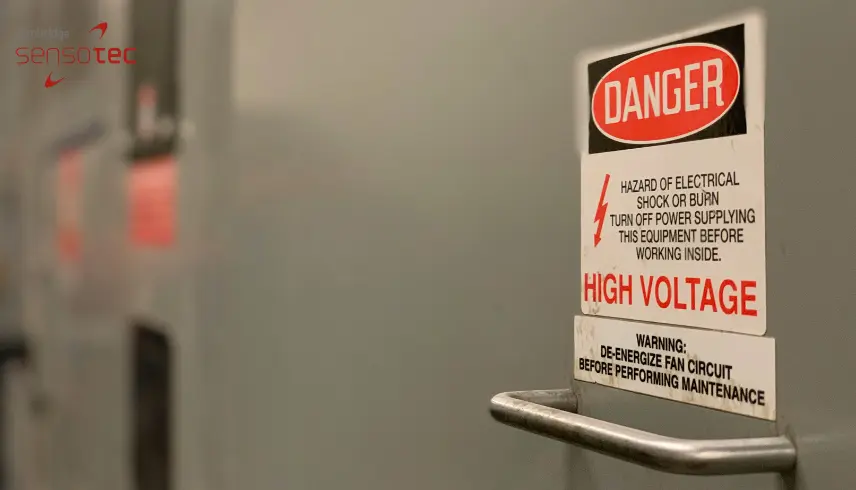

SF6 is widely used because of its excellent electrical insulation and arc-quenching properties. However, its benefits come at a significant environmental cost. When released into the atmosphere—either through leaks, improper disposal, or accidents—SF6 lingers for thousands of years, contributing to long-term climate change. Even small leaks can accumulate, making lifecycle emissions a critical concern.

The European Union’s F-Gas Regulation and similar frameworks around the world are actively restricting the use of SF6 in industrial applications. Many utilities are now facing increased compliance requirements, higher maintenance costs, and growing reputational risks associated with SF6 usage. The urgency to replace this gas is no longer theoretical—it is fast becoming a legal and operational necessity.

Why SF6-Free Switchgear is the Logical Evolution

SF6-free switchgear technologies are designed to match the performance of their SF6-based counterparts without the environmental drawbacks. Innovations such as DryAir and vacuum insulation offer reliable alternatives that meet international standards for safety and efficiency. These technologies eliminate the need for gas recovery systems, reduce maintenance complexity, and eliminate the risk of SF6-related emissions.

In addition to environmental benefits, SF6-free solutions often come with improved operational reliability. Many systems offer modular designs that simplify installation and upgrades, helping utility providers future-proof their infrastructure. With increased funding for green technologies and energy-efficient upgrades, the case for SF6-free switchgear continues to strengthen.

Emerging technologies are also enabling smart grid compatibility. SF6-free switchgear can integrate more easily with digital monitoring tools and remote diagnostics, offering enhanced asset management and real-time performance data. This supports a more resilient and responsive energy network that meets the evolving demands of consumers and regulators alike.

In regions with rapidly expanding renewable energy production, SF6-free switchgear is also proving to be an essential enabler. As solar and wind installations grow, grid operators must ensure flexibility and reliability in their systems. SF6-free technology accommodates these dynamic loads while supporting a low-carbon energy transition.

Furthermore, the shift toward electric vehicles (EVs) and decentralised energy systems requires electrical networks that are both adaptable and environmentally responsible. SF6-free switchgear enables this evolution by providing reliable performance with minimal environmental trade-offs. As more EV charging stations are deployed and microgrids become commonplace, grid flexibility will be key—and SF6-free systems are designed to deliver on that front.

Regulatory Momentum and Industry Adoption

Global policy changes are paving the way for widespread adoption of SF6-free technologies. The European Commission has already proposed a complete phase-out of SF6 in new equipment across several voltage levels. National regulators in countries such as Germany, the UK, and Japan are aligning with similar initiatives to curb emissions in the power sector.

Major players in the electrical infrastructure space are already investing in SF6-free innovations. By taking proactive steps, these companies are not only complying with future regulations but also gaining a competitive edge. According to market trends, SF6-free switchgear is set to dominate new installations by the end of the decade.

Case studies from across the energy sector show positive results. Utilities that have adopted SF6-free systems report lower maintenance costs, simplified compliance, and improved public perception. These early adopters are setting a precedent for widespread change across global energy markets.

Industry associations and collaborative projects are also accelerating the shift. Initiatives like CIGRÉ and EU-funded innovation programs are supporting research and knowledge-sharing across borders. These efforts help standardise performance benchmarks and give utility providers the confidence to invest in SF6-free switchgear.

Benefits Beyond Emissions Reduction

The transition away from SF6 is about more than just cutting emissions. Adopting SF6-free switchgear contributes to broader environmental, social, and governance (ESG) goals. It signals a commitment to innovation, environmental responsibility, and long-term asset performance.

Additionally, maintenance crews benefit from safer working conditions due to the absence of toxic or high-pressure gases. With fewer special handling requirements and a lower risk of gas leaks, the switch to SF6-free infrastructure also supports occupational safety.

Another often-overlooked benefit is cost predictability. With SF6 supplies becoming more regulated and expensive, moving to SF6-free alternatives can protect organisations from future price volatility. This offers both operational stability and stronger long-term financial planning.

Furthermore, embracing SF6-free solutions demonstrates corporate leadership. Companies at the forefront of this transition can build stronger relationships with investors, regulators, and environmentally conscious customers. These reputational benefits can open new business opportunities and enhance long-term brand value.

In an increasingly competitive and transparent marketplace, businesses are being judged on their environmental choices. SF6-free technology provides a clear, visible commitment to sustainability—an attribute that resonates with stakeholders, customers, and policymakers alike. From brand image to bottom-line impact, the rewards of going SF6-free extend far beyond emissions alone.

Internal Link: Related Technologies

For a closer look at one of the most promising alternatives, explore our article on DryAir Technology and Sustainability Standards, which details how DryAir aligns with global climate goals.

Internal Link: End-of-Life Management

To understand how proper disposal and recycling can complement SF6-free technologies, read our post on SF6 Recycling Best Practices.

The Future is SF6-Free

As countries commit to net-zero targets and the grid becomes more decentralised and digital, the demand for clean, reliable, and future-ready infrastructure will continue to grow. SF6-free switchgear is no longer a niche innovation—it is the direction in which the industry is heading. Those who invest early will benefit from reduced environmental liabilities, improved operational efficiency, and enhanced brand reputation.

Energy distribution is evolving, and with it comes a responsibility to implement systems that align with a sustainable future. By moving away from SF6 and embracing greener alternatives, utilities and infrastructure providers are playing a critical role in shaping tomorrow’s energy landscape.