Alternatives to SF6: An Introduction

SF6 gas, or sulphur hexafluoride, is widely used in the electrical industry due to its exceptional insulating properties. However, its significant environmental impact has necessitated a search for alternatives. This article explores the negative environmental effects of SF6, particularly in switchgear, and discusses regulations pushing for a transition. It also delves into dry air as a promising alternative.

Understanding SF6 Gas

What is SF6 Gas?

SF6 is a synthetic gas composed of one sulphur atom and six fluorine atoms. It is non-toxic, non-flammable, and highly stable, making it an ideal insulating and arc-quenching medium in electrical applications.

Common Uses in Industry

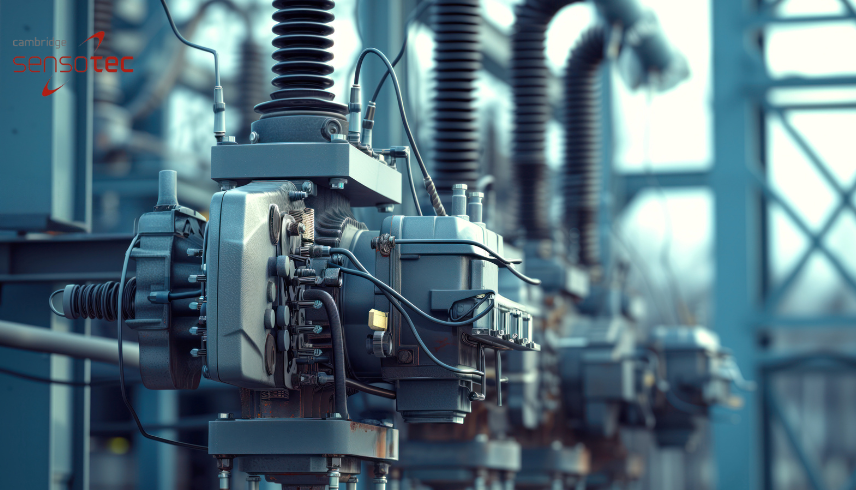

SF6 is primarily used in the electrical industry for gas-insulated switchgear (GIS), circuit breakers, and transformers. Its excellent insulating properties make it invaluable for preventing electrical faults and ensuring safety.

SF6 Gas in Switchgear

In switchgear, SF6 acts as both an insulator and a quenching medium for electrical arcs. Its high dielectric strength and thermal stability enable the construction of compact and efficient switchgear units.

The use of SF6 in electrical equipment provides numerous advantages, including high reliability, low maintenance, and the ability to operate under extreme environmental conditions. These benefits have made SF6 the standard insulating medium for high-voltage applications.

Environmental Impact of SF6 Gas

Greenhouse Gas Potential

SF6 is a potent greenhouse gas with a global warming potential (GWP) 23,500 times that of carbon dioxide (CO2) over a 100-year period. This high GWP makes even small leaks significant contributors to climate change.

SF6 has an atmospheric lifespan of approximately 3,200 years, meaning that once released, it remains in the atmosphere for millennia, continuously contributing to global warming.

Emissions and Leakage

Emissions of SF6 occur during manufacturing, maintenance, and disposal of electrical equipment. Leakage can also happen during normal operations, further exacerbating its environmental impact.

SF6 leakage contributes significantly to the greenhouse effect. Even small quantities can have a substantial impact due to its high GWP and long atmospheric lifespan, making it a major concern for environmental sustainability.

Regulatory Pressure & Guidelines

International Agreements

International agreements such as the Kyoto Protocol and the Paris Agreement have highlighted the need to reduce greenhouse gas emissions, including SF6, prompting countries to take action.

Regional Regulations

Many regions, including the European Union, have implemented stringent regulations to limit SF6 emissions. These regulations mandate regular monitoring, reporting, and, in some cases, phasing out of SF6 in favour of greener alternatives.

Future Regulatory Trends

The trend towards stricter regulations is expected to continue, with increasing emphasis on sustainable practices and reducing the environmental footprint of industrial activities.

Alternatives to SF6 Gas

Criteria for Suitable Alternatives

A suitable alternative to SF6 must offer comparable insulating and arc-quenching properties, be environmentally friendly, and be cost-effective. It should also be safe, reliable, and compatible with existing electrical infrastructure.

Comparison of Alternatives

Various alternatives to SF6 are being explored, including dry air, G3 (Green Gas for Grid), Novec 4710, and solid and vacuum insulation. Each has its advantages and limitations, depending on the application.

Dry Air as an Alternative

What is Dry Air?

Dry air is air with a very low moisture content, achieved through drying processes. It can be used as an insulating medium in switchgear, providing an eco-friendly alternative to SF6.

Benefits of Using Dry Air in Switchgear

Dry air offers several benefits, including zero global warming potential, no toxic by-products, and the ability to be easily sourced and replenished. Its use can significantly reduce the environmental impact of electrical equipment.

Technical and Performance Considerations

Dry air requires careful management of moisture levels to maintain its insulating properties. It may necessitate design modifications in switchgear to ensure effective insulation and arc quenching.

Other Alternatives

G3 (Green Gas for Grid)

G3 is a mixture of carbon dioxide and C4, developed by GE, offering a much lower GWP than SF6 while providing similar insulating and quenching performance.

C4 Gas

C4 gas, a 3M product, is another alternative with a significantly lower GWP than SF6. It is used in combination with other gases to provide effective insulation.

Solid and Vacuum Insulation

Solid and vacuum insulation are emerging as viable alternatives, particularly in medium-voltage applications. These methods eliminate the need for gas entirely, thereby avoiding greenhouse gas emissions.

Conversion to Dry Air

Retrofitting Existing Switchgear

Retrofitting existing switchgear to use dry air involves replacing SF6 with dry air while ensuring that the equipment maintains its insulating and arc-quenching capabilities. This may require modifications to sealing systems and other components.

Design Considerations for New Equipment

Designing new switchgear for dry air involves optimising the layout and materials to maximise insulation efficiency. This includes using materials resistant to moisture absorption and corrosion.

Economic Considerations

Cost-Benefit Analysis

While the initial cost of converting to dry air can be high, the long-term benefits often outweigh these costs. Reduced environmental impact, lower regulatory compliance costs, and potential energy savings contribute to a favourable cost-benefit profile.

Long-term Savings and Efficiency

Dry air systems tend to have lower maintenance costs and improved reliability, leading to long-term savings. Additionally, avoiding the use of a potent greenhouse gas can have economic benefits related to regulatory compliance and corporate sustainability goals.

Implementation Challenges

Technical Barriers

Technical challenges include ensuring that dry air systems meet the same performance standards as SF6 systems. This requires careful engineering and testing to overcome potential barriers.

Regulatory and Compliance Issues

Compliance with existing regulations and standards can be complex, particularly when transitioning to new technologies. Ensuring that dry air systems meet all necessary certifications is crucial for successful implementation.

Training and Skill Development

Transitioning to dry air requires training personnel in new maintenance and operational procedures. Developing the necessary skills and knowledge is essential for the safe and effective use of dry air in switchgear.

The Future of Gas Insulation in Switchgear

Emerging Technologies

Ongoing research is focused on developing new insulating gases with low environmental impact. Innovations include advanced gas mixtures and entirely new compounds that offer better performance and lower GWP.

Switchgear design is evolving to accommodate new insulating technologies. Advances include more compact designs, improved materials, and enhanced safety features, all contributing to more sustainable electrical infrastructure.

Industry Trends and Predictions

The adoption of alternatives to SF6 is expected to grow as regulatory pressures increase and environmental awareness rises. Early adopters are likely to gain a competitive edge by demonstrating commitment to sustainability.

Future Regulatory Landscapes & The Need For Alternatives To SF6

Future regulations are expected to become even stricter, further driving the need for environmentally friendly alternatives to SF6. Companies that proactively adopt greener technologies will be better positioned to comply with these regulations and avoid potential penalties.